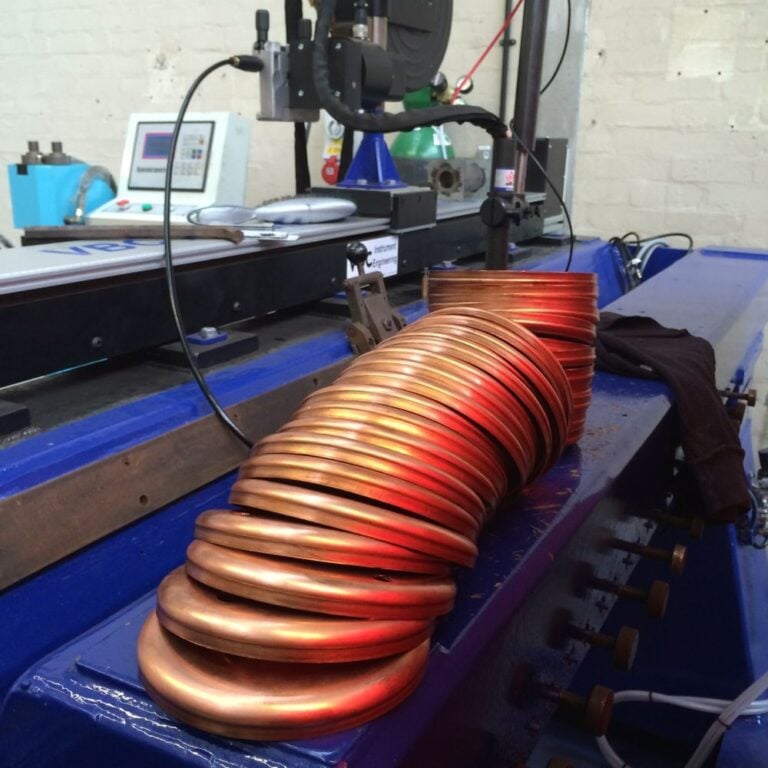

Pressed copper sheet for LONDINIUM I boilers ready to roll

This stack of stamped copper sheet is about to be transformed into a large pile of LONDINIUM I boilers

This stack of stamped copper sheet is about to be transformed into a large pile of LONDINIUM I boilers

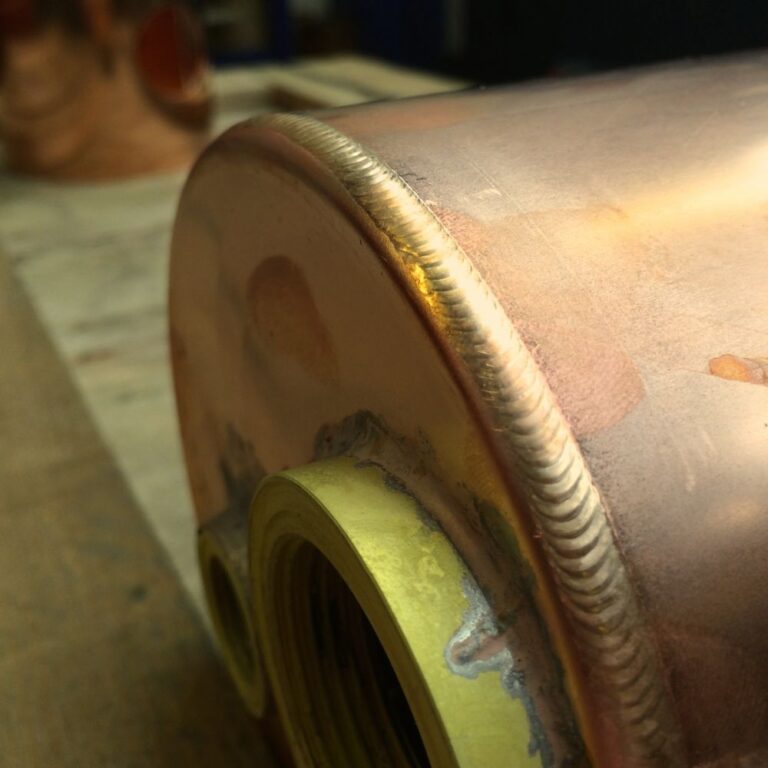

these are what nice, secure welds on copper look like – a first class job.

in the near future we expect to see the LONDINIUM III boilers stacked in neat piles close to this stock location we are pleased to confirm that we have worked our way to the front of the development queue and…

unparalleled thermal conductivity and highly malleable – it is the best material for the manufacture of boilers, far preferrable to stainless steel

lots of space for lots of boilers

this clip shows the brass fittings, to which all the pipes are mounted, being brazed into the body of the copper boiler all these activities are now being performed in-house at Birmingham, England

this is a short clip showing a sheet of copper being roll formed to create the body of the boiler, albeit this one is for a two group machine the rolled sheet is then welded down the join, after which…

these are the end caps for the boiler for the LONDINIUM I that we now manufacture entirely in-house at Birmingham, England the body of the boiler is roll formed from a piece of copper sheet, which is then welded down…

i visited our manufacturer in Birmingham, England today and here is an image of the new boilers for the LONDINIUM I lever espresso machine that we are producing inhouse. we are very pleased with the quality, and critically it ensures…

UPDATE: 25APR2014 – this machine is now sold. we have received a roll call of requests to sell this machine to individuals located outside of the UK – Germany, Singapore, Middle East, Australia, you name it the snag is we…